1807-1

DESCRIPTION:

1807-1 adhesive is a high strength, two component, Epoxy Resin system designed primarily for core bonding and composite to composite bonding of large laminates. It is ideally suited for the bonding of main load bearing structures in Wind Turbine Blade assembly. It is available in different curing speeds allowing processing over a large range of ambient temperatures.

APPERANCE:

1807-1- AB (Epoxy Resin)

Density at 20 0c (ISO 1675) 1.40– 1.45 g/cm3

Flash Point (ISO 2719) > 120 0c

1807-1A-AHA / 1807-1B-AHA (Adhesive Hardener)

Density at 20 0c (ISO 1675) 0.9– 1.00g/cm3

Flash Point (ISO 2719) > 120 0c

APPLICATION DATA: Mixing

Mixing Ratio by weight 100 Parts 1807-1 resin to 35±3 Parts 1807-1 hardener

Mixing Ratio by Volume 100 Parts 1807-1 resin to 48±3 Parts 1807-1 hardener

The components should be mechanically mixed thoroughly at medium speed ensuring that no unnecessary air is entrained. Both sides and bottom of container should be scraped during mixing process.

Suggest using the mixing machine to mix the resin and hardener, which can avoid the generation of microbubble efficiently and make the properties of material into full play. The manufacturers of mixing machine are as follows: 2KM,Dekumed, Graco, Dopag/Huk and so on.

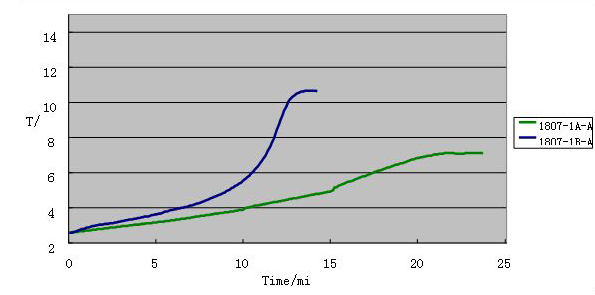

APPLICATION DATA: Working Temperature Geltime /Peak Exotherm:500g at 210c -230c

Tg (ISO 11357) Curing conditions:8hr 80 ℃

Tmg

1807-1-AB /1807-1A-AHA >85℃

1807-1-AB /1807-1B-AHA >85℃

Tensile shear strength( DIN EN 1465-2009) Test piece material:Aluminum alloy AA2024-T3

Tensile shear strength

1807-1-AB /1807-1A-AHA >20MPa

1807-1-AB /1807-1B-AHA >20MPa

T - stripping test (ISO 11339-2010) Test piece material:5754H111

T – stripping strength

1807-1-AB /1807-1A-AHA >2N/mm

1807-1-AB /1807-1B-AHA >2N/mm

Tensile Property (ISO527) Dumbbell type

Tensile strength Tensile modulus Tensile elongation at break

>45MPa >3700MPa >1.6%

Impact Ductility(ISO 179-1:2000)

Test Condition Impact Ductility

23℃ ≥10kJ/m2

50℃/2h ≥10kJ/m2

-40℃/2h ≥10kJ/m2

Note:

1807-1-AB | 1807-1A-AHA(Standard) |

1807-1B-AHA(Fast) |

Certifications and Approvals:

Date of Printing: September 2015- supersedes all previous issues

IMPORTANT NOTE:

The specification listed above is given to the best of our knowledge, however, it is given without any warranty expressed or implied. The specification is subject to change without notice. Consult QUALITY CONTROL REPORT available for each Batch for actual results. Consult MATERIAL SAFETY DATA SHEET for handling of material.