3216FR Epoxy Resin

DESCRIPTION:

The production is mainly applied in fire retardant level requirement of fiber reinforced composite material structures, such as rail transportation, yachts, car interiors and part structure composite material. This resin composite material structure, when heated and close to the fire will not release toxic and harmful gases. Especially suitable for infusion process, RTM process (low viscosity and low surface tension of resin can quickly be capillary action, fully infiltrate various reinforced material) and had lay-up process. 3216FR resin with 3216AH is for infusion process; 3216FR resin with 3216BH is for hand lay-up process.

Technical requirements of components:

NO. | Items | 3216FR | 3216AH |

1 | Appearance | No Obvious impurity | |

2 | Viscosity 25℃,mPa·s | 900~1400 | 30-50 |

3 | Epoxy equivalent g/Eq | 188.0 | |

4 | Amine value mg KOH/g | 562.5 |

The resin blend system technical requirements:

NO. | Items | 3216FR+3216AH |

1 | Viscosity 25℃,mPa·s | 400~650 |

2 | Exothermic peak time 25℃/100g,min | 180-200 |

Typical performance of resin casting:

After exothermic peak at room temperature curing, curing at 80℃ by eight hours

NO. | Items | 3216FR+3216AH |

1 | Tensile strength(Mpa) | 65 |

2 | Tensile modulus(Gpa) | 3.0 |

3 | Elongation(%) | 4.0 |

4 | Bend strength(Mpa) | 120 |

5 | Bend modulus(Gpa) | 3.0 |

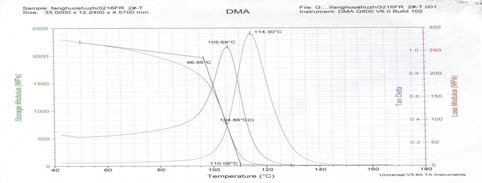

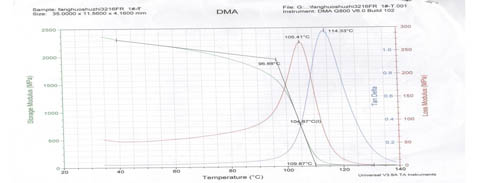

6 | Tg(℃,DMA Tan delta) | 115 |

This date is the average data for the laboratory test data.

Flame retardant performance of resin casting:

NO. | Standard | Items | Result |

1 | UL | V0 | |

2 | DIN 5510-2 | Buring level Smoke level Drip level | S3 |

SR2 | |||

ST2 | |||

3 | ISO 5658-2 | 19.0 CFE(kW/m2) | |

4 | ISO 5660-1 | 102.4 MARHE(kW/m2) |

Concentration of harmful gas after combustion:

Test Item | Technical requirement | Unit | Test Result | Note | |

Concentration of harmful gas after combustion | CO | <4000 |

Mg/m³ | 920 | / |

CO2 | <90000 | 8070 | / | ||

HF | <82 | 2 | / | ||

HBr | <330 | 5 | / | ||

HCL | <150 | Not detected | Detection limit 0.2 mg/m³ | ||

HCN | <110 | 3 | / | ||

SO2 | <260 | 8 | / | ||

NOX(use NO2 measuring) |

<190 | 8 | / | ||

NOTICE: The client should provide glass fiber reinforced plastics laminate with gel coat as roof facing material | |||||

Product DMA Test 1:

Product DMA Test 2:

Recommended curing process:

3216FR epoxy resin system can curing at high than 15℃,if need to get the best mechanical properties and thermal properties, must be conducted under the condition of temperature after curing. Recommended to curing at room temperature after exothermic peak, after the exothermic peak, temperature to 80℃,the curing after 10 hours. Concrete curing temperature, curing time and heating rate should be carried out according to the product structure adjustment, to ensure that products fully cured.

Issued Date: September 2015- Supersedes all previous versions

DISCLAIMER:

The information provided herein is given to the best of our knowledge, however, it is given without any warranty expressed or implied and MID assumes no liability in connection with any use of this information. The specification is subject to change without notice. All advice given and products sold are subject to MID’s terms and conditions of sale. Consult QUALITY CONTROL REPORT available for each batch for actual results. Consult MATERIAL SAFETY DATA SHEET for handling of material.